Our Core Services

A core service refers to the main benefit that customers receive when they avail of any service. It is the primary objective of the transaction and provides measurable value to beneficiaries, such as citizens, businesses, and local government units. Identifying your core product or service gives you clarity and helps to shape your marketing and sales messaging.

High Voltage Department

➢ High and Medium AC motors.

➢ Repair to motors up to 3500kw.

➢ Balancing – Outsourced.

➢ VPI (Resin) – Outsourced.

➢ Vibration testing – Vibepro.

➢ Turnaround times, from receipt of an official order,

Normal: TBA.

Breakdown: TBA.

*Depending on the scope of work

High Voltage Coil Department

➢ Set Diamond Coils up to 2500Kw.

➢ Coils.

➢ Rotor Rebar.

➢ Rotor Rewind.

➢ All Electric Testing.

High Voltage Test Department

➢ No load test capabilities on all MV motors up to 6600V.

➢ Bar Continuity Testing.

➢ Electromagnetic Core Imperfection Detection Testing. (EI Cid)

➢ The testing program for efficiency was designed by Henry Du Preez.

➢ Core Testing – Infrared Camera to detect hot spots. (Rotors & Stators)

Low Voltage Motor Department

➢ Repair LV AC Motors up to 1000Kw.

➢ Voltage Ranges from 220V to 1000V.

➢ Bar Continuity Testing.

➢ Scraper Winch Motors.

➢ Vibrator Motors.

➢ Flameproof Motors.

➢ Spark Proof Motors.

➢ Dust Ignition Proof.

➢ We can repair a large number of units per month.

➢ Turnaround times, from receipt of an official order,

Normal: 5 – 10 days.

Breakdown: 24 – 72 hours.

*Depending on the scope of work

Low Voltage Pump Department

➢ All types of Submersible pumps up to 250Kw.

➢ Centrifugal pumps up to 250Kw.

Multi-stage centrifugal pumps up to 16 stages.

➢ Mechanical pumps up to 250Kw.

➢ Balancing Bar.

➢ Continuity Testing.

➢ Large quantity of pump units per month.

➢ Turnaround times, from receipt of an official order.

Normal: 5 – 10 days.

Breakdown: 24 -72 hours.

*Depending on the scope of work

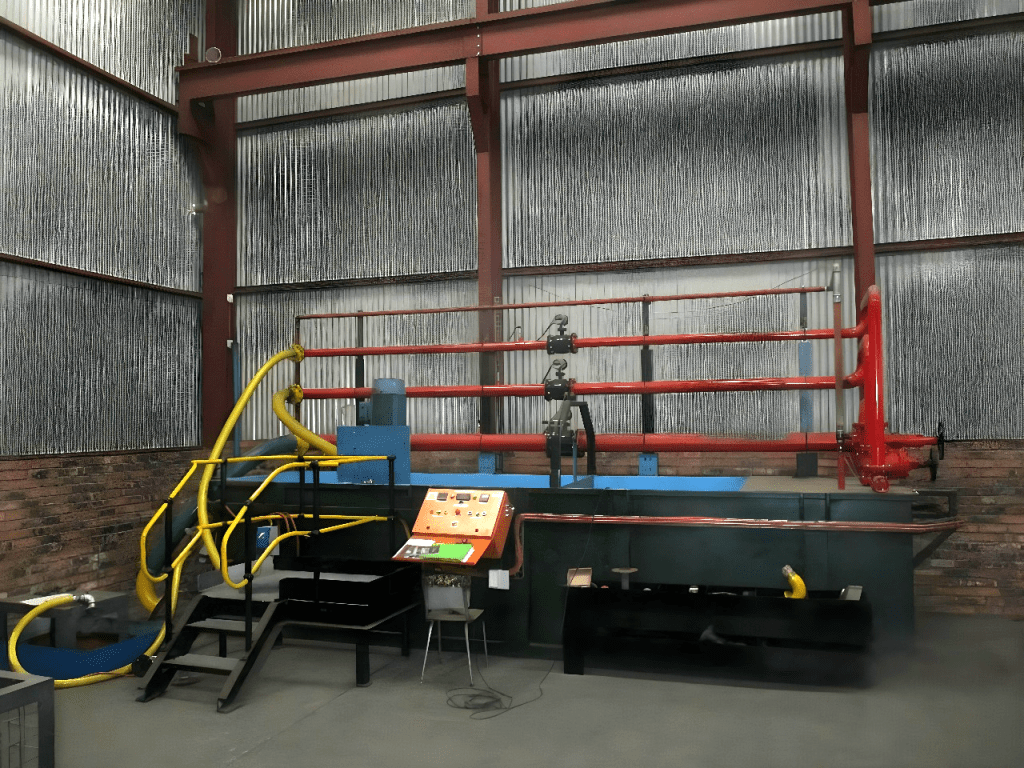

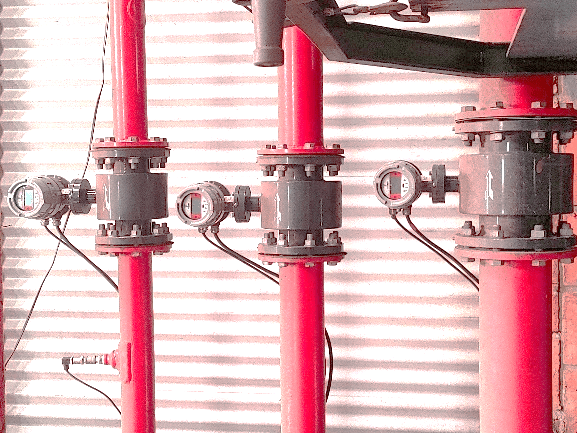

Low Voltage Pump Testing Station

➢ Testing based on KW vs. HYDRAULICS.

➢ Station capable of testing up to 200CM3 p/h on 200mm pipe.

➢ Based on 4 different sizes of electromagnetic flow meters, Namely: 50mm / 80mm / 100mm / 150mm pipe.

➢ Software to work out Friction Loss, the Flow, and the Head has been measured on different pipe sizes and calibrated to give an accurate reading of the performance of the pump.

➢ The printouts give all the information regarding the test, Namely: Head, Flow performance.

➢ The tests are performed on different readings,

The valve completely opened. Valve opened at 75% / 50% / 25% / completely opened.

Direct Current Department

➢ Repair to all DC & Winder Motors up to 300KW.

➢ Traction Motors.

➢ Alternators.

➢ Electromagnets.

➢ Welding Machines.

➢ Balancing.

➢ Large quantity of motors per month.

➢ Turnaround times, from receipt of an official order,

Normal: 2 – 5 weeks

Breakdown: 1 – 2 weeks

*Depending on the scope of work

Direct Current Traction Motor Department

➢ Repair to all types of Traction Motors.

➢ Balancing.

➢ Large quantity of motors per month.

➢ Turnaround times, from receipt of an official order,

Normal: 2 – 5 weeks.

Breakdown: 1 – 2 weeks.

*Depending on the scope of work

Direct Current Test Department

➢ No load testing capabilities up to 2000kw.

➢ Back-to-back load testing of Loco Motors.

Transformer Department

➢ Repair Capability up to 1000 KVA.

➢ Oil Type.

➢ Dry Type.

➢ Electromagnets.

➢ Large quantity of transformers per month.

➢ Testing with multi-meter and insulation tester.

➢ Turnaround times, from receipt of an official order,

Normal: 2 – 5 weeks.

Breakdown: 1 – 2 weeks.

*Depending on the scope of work

Transformer Test Department

➢ Test capability up to 1000 KVA.

➢ Routine Testing per SANS 780.

Machine Shop Department

➢ 4 Metal Lathes.

➢ Milling Machine.

➢ Band Saw.

➢ Power Saw.

➢ Boiler making and Fabrication.

➢ Concentricity Checks.

Site Services Department

➢ On-site problem-solving.

➢ Removal, Installation, and Commissioning of motors and equipment.

➢ Removal of white metal bearings for the repair or re-metaling.

➢ Laser Alignment.

➢ Electrical and Mechanical Repairs.

➢ On-Site Quality Analysis.

➢ Replacement of brushes on DC and slip ring motors.

➢ Checking of brush gear – Neutral Point.

➢ Undercut & Bevel Commutator.

➢ Thermography.

Electrical Testing:

➢ Insulation Resistance (Megger) and Polarization Index (P.I).

➢ Winding Resistance.

➢ Interturn Test.

Mechanical Testing:

➢Bearing Temperature measurement.

➢ Vibration Analysis.